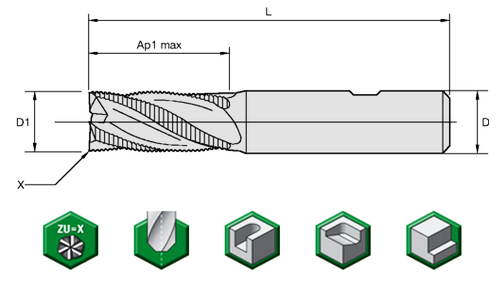

roughing end mill diagram

DIA316 FL58 OAL2 SHK316. 316 Carbide Roughing End Mill 4 Flute Fine Pitch 30 Helix AlTiN.

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

Some inch sizes below are linked below to make it.

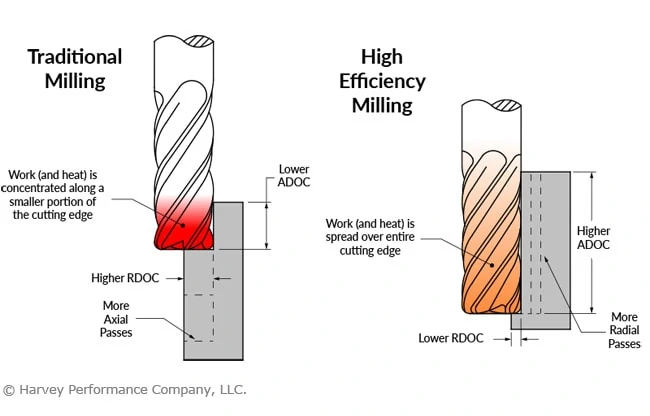

. This spreads wear evenly across the cutting edge dissipates heat and reduces the chance of tool failure. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEMHEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC. Speed and feed on solid carbide end mill drills tap and more technical information and How-to.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Coarse pitch is used for deep slots or profiling when you have to take off a lot of material. Axial Runout The difference between the highest and lowest indicator reading that is taken at the face of a cutter near the outer.

For fast cuts and the greatest rigidity use shorter end mills with larger diameters. 5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from.

If playback doesnt begin shortly try restarting your device. Fine pitch is better for lighter cuts in hard materials and will leave a better finish so that clean up with a standard end mill is easier. More on this Product Distributors Order Online.

Carbide Square End Mills. Great for large surface area work roughing end mills have numerous serrations teeth in the flutes to quickly remove large amounts of material leaving a rough finish. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

As you can see from the diagrams above we depict how our tooling geometry on our end mills can have up to 3 rake faces on the cutting edge of the tool. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Since the radial relief angle of end mill is 11 degree the diminution Δr of radius of end mill is 34 μm tan 11 deg.

The cut that an Angular edge tool produces will not be as flat as a helical cutting edge. These lower the shock load during the cutter rotation both enabling a heavier cutting load. As the tool enters the cut and takes the first 3-5 revolutions and remember you can be running up to 18000 Revolutions Per Minute to create a fully formed 6 or 9 shaped chip.

Cutting edges are only on a top. 316 Carbide Roughing End Mill For AL 3 Flute Coarse Pitch 45 Helix Uncoated. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

Large temperature variations occur at the surface region of the work-roll owing to severe temperature. Some end mills with fewer flutes are called roughing end mills as the fewer flutes mean. The flatted shank can be used in a conventional holder.

Side milling curved surface milling and drilling are possible only by one. Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts chips away from the cutting action. Mar 1 2017.

1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50 70 1000 2000 3000 4000 5000 6000 Roughing End Mills for Aluminium Wide variation Highly efficient Roughing. End mill A multi-functional tool which has cutting edges on the periphery and an end face. This table shows end mill diameter sizes for inch metric and micro milling bits from 0005 to 1.

Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded. As you can see a chain of holes are plunged vertically with the tool to rough out most of the pocket area. Angular Edge The cutting edge that is a straight line and forms an angle with the cutter axis.

Normally a 20 reduction in effective horsepower is used. Variable helix end mills reduce chatter and vibration. 66 μm after about 10 hours passed.

You do have to use a mist coolant system to get the chips out of the slot flood coolant or oil will not work there. Apply coatings for higher feeds speeds and tool life. The second pass called the finishing pass then wont require as aggressive of a cut and can provide a smoother finish at a high speed.

Figure 7 shows the tool wear of the end mill after about 0 10 and 20 hours passed in real gear machining. They are sometimes referred to as Corn Cob cutters or Hog Mills - so called after the pig who grinds away or consumes anything in its path. DIA316 FL58 OAL2 SHK316.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. All of these sizes can be searched by clicking the End Mills tab at the top of the page. Use cobalt PMPlus and carbide on harder materials and high production applications.

End Mill Size Chart pdf The above link provides a printable and downloadable chart of the table below. Diagram of solid carbide end mills Essential Summary. Download scientific diagram Dimensions of the roughing mill components and side guide.

Drill A tool for drilling. Duane there are fine and coarse pitched roughing end mills for steels and aluminum too. Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone.

Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1. The first pass called the roughing pass can be done by using an end mill that will eject a large number of chips at a high feed rate. The graphic shows a typical plunge milling operation for a square pocket courtesy of BobCAD.

The length of tool wear of the cutting edge was about 34 μm. Roughing End Mills - Cobalt and High Speed Steel. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

A subsequent finish pass will complete the pocket. The spiral flute end mill compared to a straight flute does a similar function. The Mechanism of Position-Mode Side Guide in.

A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation. Roughing endmills will take a cut the full length of the mill in a pass to cut a slot at a faster rpm and feed than a standard endmill.

Lfc Widia End Mills 4s0r 4s4r Series

Roughing End Mill Kyocera Unimerco

Pin On Woodworking Tips Tricks And Hacks

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

Cutting Forces In End Milling Download Scientific Diagram

Programming Tutorials Cnc Programming C C Assembly Python Java Arduino Ebooks Cnc Programming Cnc Programmer Cnc

End Mill An Overview Sciencedirect Topics

G90 And G91 G Codes In 2021 Arduino Cnc Coding Cnc Machine

Room Planning Kitchen Floor Plan

8 Ways You Re Killing Your End Mill In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

Mastercam 2021 Tutorial 93 Mill 3d Machining Mold Youtube In 2021 Mastercam Tutorial Molding